Projects 2

A Number of the smaller projects that I have built or worked on over the past 10 or so years.

This little unit is a first pass at a quiz buzzer- it will probably be upgraded at a later stage to have some other functions, but it worked well for the event it was made for.

Each year a group of my friends have a large BBQ/ party in their garden, known as Ricefest. There are always a number of games/ challenges/ competitions held. This time one of them was to be a version of ‘Family Fortunes’, so I put together the buzzer unit for it.

The system is largely made of scrap parts that I already had lying around- the only things needed to be bought were two diodes, and the sparkly holographic covering material.

There are a number parts to the system;

Power Supply & cabling

In the past I have made use of 12V to run systems like this I have built, and years ago settled on using XLR connectors to connect parts together. This means that each time I built something new (lamp unit, bell, switch box etc) I could connect it up easily without having to make up new cables each time. I chose XLRs as the three pin version is rated at 15A, so plenty of current for most of what I was likely to build, they are relatively easily available at sensible prices, and are robust.

I have over the years been building up quite a few industrial control parts, all of which operate on 24V. As there were a number of these that I wanted to use in this project (most importantly the sounder, but even not buying lamps would save a bit of cash), I decided to put together a 24V power supply. This was relatively simple, although there are a couple of tweaks to be made.

Firstly, to connect the parts together I have started to use the 3rd pin in the XLRs to carry the 24V and keep a common –Ve.

I started the PSU by selecting a transformer. I was lucky enough to have a DIN rail mounting, 50VA encapsulated unit with 12 and 24V coils and screw connections that came out of a piece of industrial equipment at a local scrap-yard. This was mounted in a second-hand die-cast aluminium box that I had been given a few years ago using a piece of DIN-rail, also from the scrap-yard. The power inlet is a fused IEC socket removed from a piece of redundant equipment and wired to the input coil on the transformer.

The output is rectified using a bridge rectifier salvaged from an old switch mode PSU. There is no smoothing yet- this will be done using a capacitor when I dig one out. The output of the rectifier is therefore wired via a 2A aircraft circuit breaker (rescued from a breaker panel from a Fokker F27, also from a scrap-yard), and tested before I installed it, to an XLR socket, again removed from some no-longer needed equipment.

This was all knocked up in one evening. I also installed a second XLR socket and breaker to be able to also connect the 12V coil to, but forgot to dig out a rectifier, so this will have to wait for the time being.

I finished off by making a few safety tests.

Button Boxes

These are a pair of identical boxes consisting of an industrial plastic box, that once mounted an emergency stop on a conveyer, salvaged at the scrap yard, along with an illuminated push-button, also salvaged from the scrap yard. These are connected to a length of 3A mains cable, led out of the box through a gland, with the illumination paralleled with a ¼” jack socket which enables the sign units to be plugged in. The end of the cable is terminated in a 4 pole XLR, again from the scrap-yard.

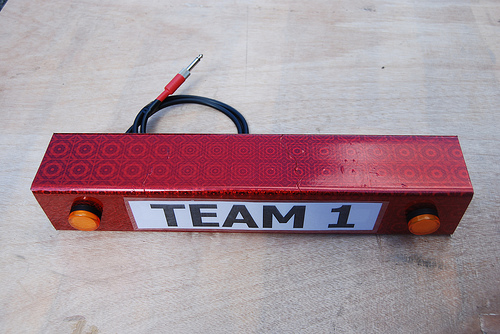

Sign Units

The basis of these is a length of plastic drainpipe approximately 500mm long. This has mounting holes drilled in it for the parts and is then covered in holographic book covering film- This proved to be the most difficult item to find, involving a trawl round more than a dozen shops in two towns before i found it- Last time I had used it for a stage set it was much easier to find (I could have bought it from a theatrical supplier but it would have cost £14/ metre!).

The cable in is connected to a surplus ¼”v plug one end, and led through a gland into the pipe. From there it connects to two industrial indicators, fitted with 24V Led lamps rescued from the scrap-yard. The team sign is a laminated piece of card stuck to the box with carpet tape.

Buzzer/ Control Unit

The last part of the system is the buzzer and control box. The intention was to make this interlocking and latching , with an indicator for each team and a reset button, so there would be no argument over who buzzed first. Unfortunately I didn’t have the right selection of relays to do the logic to hand, so for the time being I have had to be content with just having the sounder for the time being. This will be changed in the future though.

Again, most of the parts came from the scrap-yard or were rescued from other discarded equipment, including the loud industrial sounder. The only exception was the plastic box which was bought as part of a job lot at a local boot fair, so probably cost the equivalent of about 50p.