Gunge and Slime

This page

covers detail on options for making gunge and slime, as well as some of

the science behind it. If you are looking for specific recipes, and games,

either have a look at the gunge index page, or these two links;

Definitions

The

terminology for Gunge and Slime tends to vary somewhat around the

world, and between dictionaries, however in general usage Slime and

Gunge are virtually synonymous- typical UK definitions being;

Slime;

n Unpleasant thick slippery substance (1)

Gunge;

n informal Sticky unpleasant substance (1)

In

my opinion, these are not really sufficient definitions to distinguish

between the various types of mess that can be made. To come up with a

suitable definition, I believe that three properties that a fluid may

have need to be considered. These are;

Viscosity;

The resitance of a fluid to shear forces, and hence to flow (2)

Tack(iness);

Ability of a material to bond with another when contact is brief and

pressure is light (2)

Stringiness;

Like string, Fibrous (1)

If

you base the definition of gunge on that typically used in British

television shows, which I believe is how the UK public perceive a gunge

to be, then a suitable general definition would be;

Gunge;

A fluid which is viscous and tacky

Basing

the definition of slime on the familiar children's toys, I believe a

suitable definition is;

Slime;

A fluid which is viscous and stringy, especially one that also displays

tackiness

I

will therefore use these definitions for the rest of this site.

The etymology does differ to that used in the USA.

Making Gunge and Slime

Recipes for various types of gunge and slime can be found on the

seperate pages on this site. For mixing small quantities a small hand

mixer works pretty effectively. For larger quanties a drill mounted

mixer works effectively.

Mixing Items

Mixing Items

Gunge

Technology

Virtually

all the gunges used in film and television, are based on an industrial

thickening agent (gum), either a food or cosmetic ingredient, although

this is not always the case (e.g. Custard for Dick and Dom In Da

Bungalow). Technically they are usually Polysaccharides, a polymer

carbohydrate. In particular many are derivatives of cellulose, of which

there a huge range of products available.

Virtually

any commercial thickening agent could be used, but there are a number

of reasons why a restricted number tend to be selected;

Safety

This

should obviously be of prime importance- this means that the thickeners

should be products intended for food or cosmetic use. Industrial

thickeners for paints, oil well drilling etc are therefore not likely

to be appropriate.

Availability

In

most cases the industrial thickeners are not available directly to the

public. They are bulk packaged (typically in 25kg/50lb sacks) and sold

only via trade suppliers. This means that the products that are

available are those where a supplier is prepared to split a sack to

sell a small quantity- hence the dominance of natrosol in the UK and

Methyl Cellulose in the US.

Temperature

Many

of the easily available food thickeners (such as cornflour/ custard

powder, starch, gelatine etc) either need to be boiled or at least

require boiling water. Whilst this is practical for a few litres at

home, it becomes difficult to make up large batches unless you have

access to commercial kitchen facilities. Some of the industrial

thickeners are also formulated to be dry-mixed with food ingredients

and then thicken when water is added and cooked. This means these types

of thickeners are less desirable for gunge use.

Cost

Can

vary considerably, but can be difficult to compare as different

concentrations will be needed to make a mix of the same viscosity

(thickness). It is therefore best to compare the cost per litre of the

finished gunge.

Mixing

In

my opinion, the ease of mixing is probably the most important factor to

consider. The natrosol mixes very easily, but in my experience some

other thickeners (such as Guar gum) don't. For small quantities a

wooden spoon or food mixer works quite effectively. For larger batches

a paint/ plaster mixer in a drill works very effectively. To disperse

the powder into the water, I tend to measure the required amount into a

jug, and sprinkle into the water as it is being stirred. If the

thickener doesn't flow easily as a powder, I would recommend passing

through a sieve first as if the powder clumps together , it won't

disperse easily in the water and you will end up with lump (3).

When

mixing a large batch up, I would generally recommend splitting it into

smaller batches. This makes the physical handling of the gunge easier,

and reduces the risk of losing the whole batch if something goes wrong.

Typically for the events I have run where 3-400 litres have been

needed, we have split it into 50l batches. In some of these cases we

have mixed the gunge off site from where it is going to be used and

transported in 50l Screw-top plastic kegs (ex mango chutney

containers). Kegs any larger than this aren't really practical for

manual handling without special equipment (3).

Although

not directly broken down by bacterial action, the cellulose based

thickeners can be degraded by enzyme action, resulting in it becoming

watery (4). I find that this tends to happen with the Natrosol gunge

within a few days of being used.

Thickeners

A

range of thickeners that can be used for gunge manufacture

A

range of thickeners that can be used for gunge manufacture

As

already mentioned, there are a wide range of possible thickeners. In

most cases they are polysaccharides of some form. This means they are

chemically similar

to sugar and starches, and are built up from the same basic chemical

molecules- a simple carbohydrate. These are linked together to form a

long chain, making a polymer.

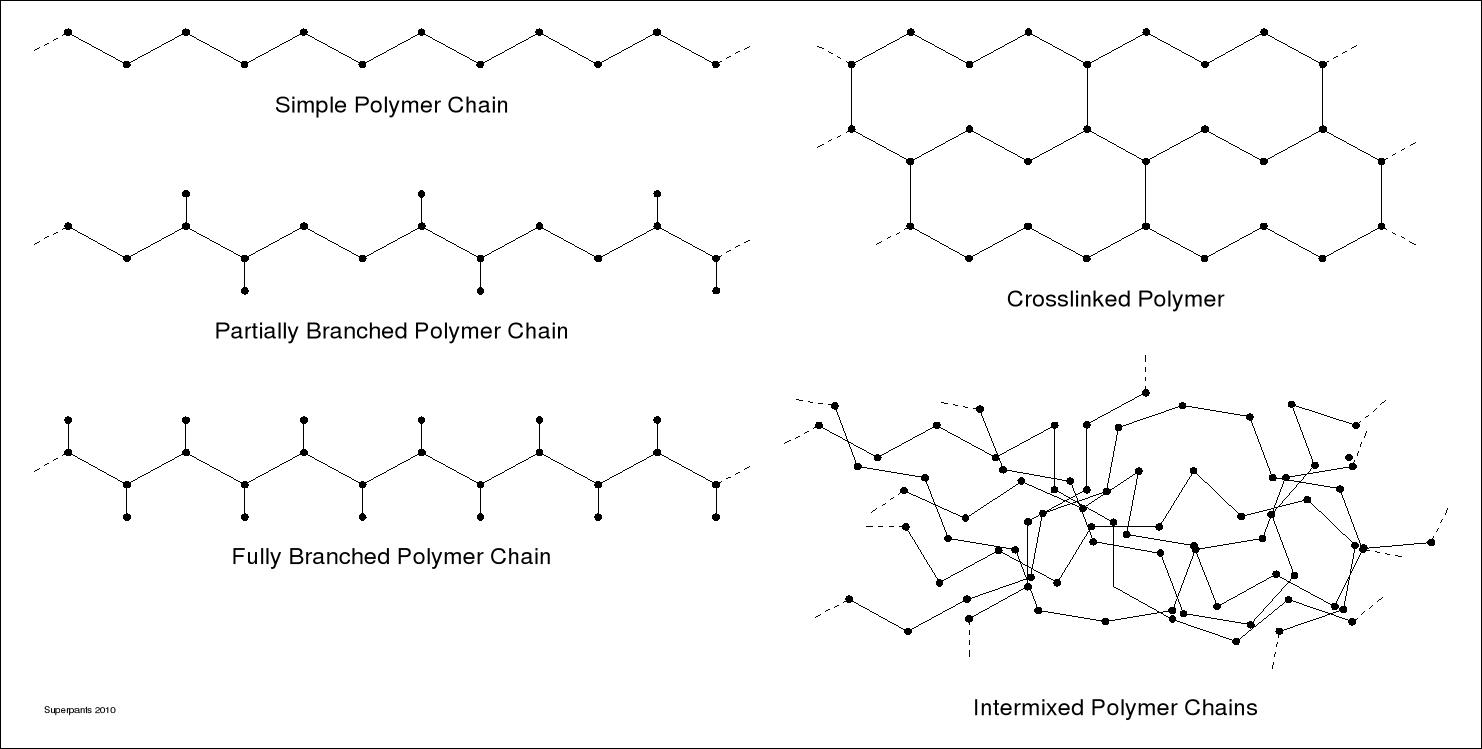

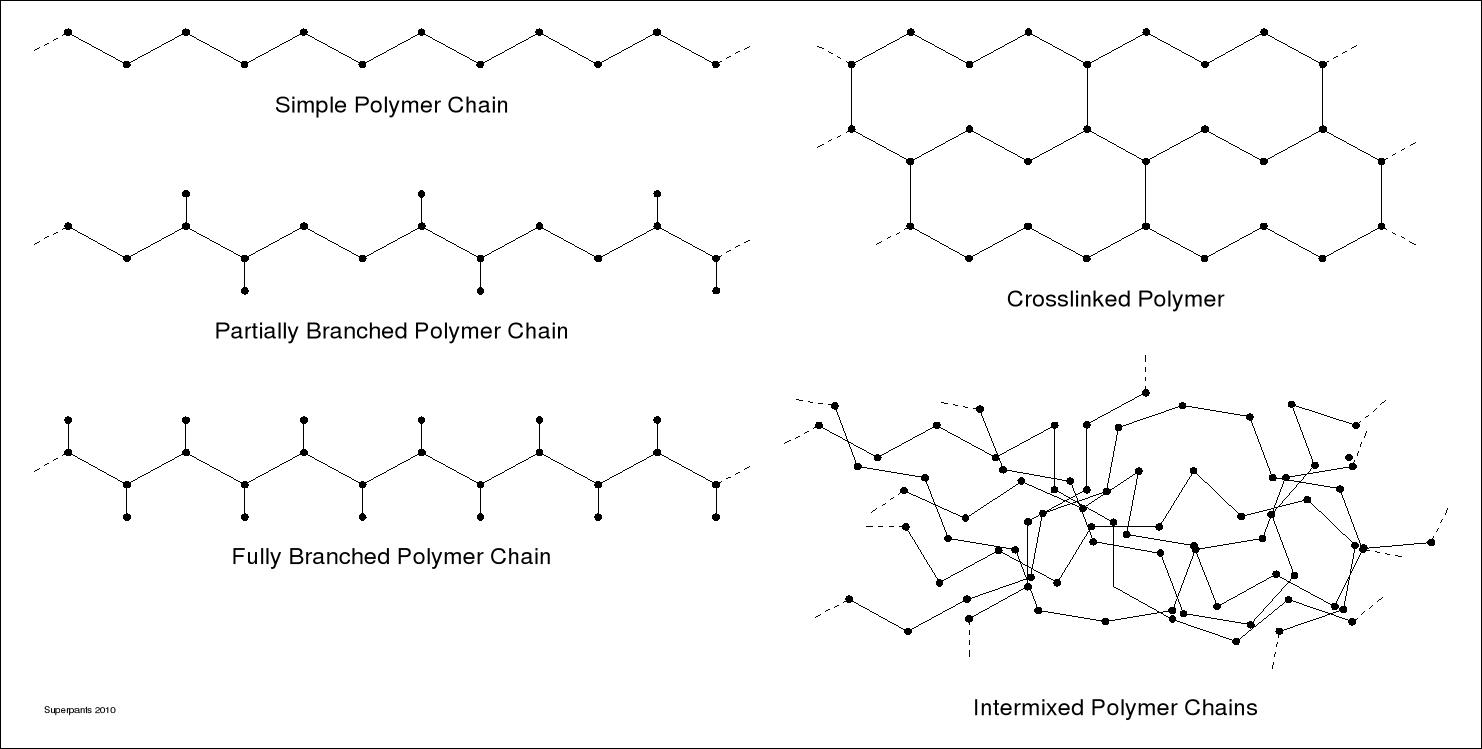

Branching

of Polymers

Branching

of Polymers

Differences

between various grades of the same material are usually down to

different lengths of polymer chain, characterised by the molecular

weight (MW) you may see on a manufacturer's datasheet, and by any

branching of the chain. As a rough and ready approximation, the longer

and/or more branchedthe

chain is, when mixed with water, the more viscous will be the resultant

gunge. Conversely, the powder will generally become more difficult to

disperse, the higher the molecular weight. I will cover the basic of

information regarding each material, as this page is only a brief

introduction to the subject. I will also cover only those

substances known to be used to produce gunge or slimes, or where I have

experience using them. There is plenty of more detailed information

available for those with a more scientific interest in the subject out

there (in particular see ref 4).

Gunge & Pink Slime made from Guar Gum

Gunge & Pink Slime made from Guar Gum

Guar

Gum (E412)

Guar

is a naturally occurring gum, extracted from the Guar (or cluster)

Bean, most of the world's supply coming from India. It is relatively

cheap, and readily available from health food stores. The first few

events I created Gunge for, I used Guar Gum which was obtained as

samples from a commercial food ingredient supplier. This worked quite

effectively when made up, but proved to be very hard work to mix- the

gum has a tendency to clump, which makes mixing it to smooth

consistency very difficult. The photo at the head of the page is of an

event at the University of Surrey Student's union using this

type. I no longer tend to use it except in the stringy slime

recipes listed below.

Xanthan

Gum (E415)

Xanthan

is the first of the commercially synthesised thickeners, being

manufactured by the fermentation by the bacteria Xanthomanas campestris

of

Glucose

or Sucrose, followed by collection, cleaning and milling. It is

available under the trade names Keltrol and Kelzan. In recent years it

has started to be used as gluten substitute, and therefore has started

to become more easily available from health food shops, larger

supermarkets in the UK and homemade soap suppliers (5). If my memory

serves me correctly, this was the material used for the Run the Risk TV

show

Cellulose

Based Thickeners

All

of these are based on cellulose extracted from vegetable matter and

then chemically treated with a range of processes to alter the

properties (viscosity, dispersion etc) to suit particular needs

Hydroxyethylcellulose

(Natrosol)

gunge

Hydroxyethylcellulose

(Natrosol)

gunge

in use, coloured with powder paint

Hydroxyethylcellulose

Possibly

the most common cellulose based thickener used for gunge, it is known

by the trade name Natrosol used by the BBC for Noels House Party

amongst other programmes (6), and widely used for charity events and

home gunging.

Methylcellulose

(E641)

A

very common cellulosic thickener, it has a wide range of commercial

uses including being the main constituent of many wallpaper pastes (7).

Known by the trade name Methocel (manufactured by Dow), its most well

known use was used in the Ghostbusters films(8,33) and the bulk of the

slime used in alien resurrection(10,11).

Others

cellulosics

Other

possible cellulose based materials that could also be used if available

include; Hydroxypropyl methylcellulose (E464)- often known as

Hypromellose, Carboxy methyl cellulose (E466) and Sodium carboxy methyl

cellulose (E467)

Super

Absorbant Polymers

Sodium

Polyacrylate/ Potassium Polyacrylate

There

are a number of chemically similar materials, generically known as

Super Absorbent Polymers (SAP), of which Sodium Polyacrylate is the

most

common type, most commonly known as the main absorbent in disposable

nappies and as a soil conditioner. A good background on the material

can be found at ref (12). Like most of the industrial thickeners, their

properties are dependent on the molecular weight and branching, but

also by the physical form the powder

is in (granules/ powder etc), giving rise to a range of possibilities

for different textures. Commercially it is available as

Gellibaff(13)(and other

bath gels). It has some major advantages in that it is easy to mix, and

the viscosity of the fluid can be massively affected by sodium chloride

(table salt), so disposal is easy as the viscosity can be dropped back

to close to that of water (14). It doesn't have good tackiness,

however, and so in my opinion doesn't make a particularly good gunge

(3).

Polyacrylamide

Polyacrylamide

is chemically similar to Sodium Polyacrylate, but is not affected by

the addition of table salt (14). Commercially it is available as

'Yuck'(15).

Polyacrylamide (aka non-ionic polyacrylamide) is used as a

soil stabiliser and water retainer in agriculture and soil remediation in mining

as well as finding uses as a lubricant in oil well drilling, and as a flocculant

in water purification (39). These chemicals are also used widely in cosmetic

applications to enhance the feel of a product, and form a stable lubricant film

on hair when dried and so finds wide use in shampoos and conditioners (40). Some

applications have also been found in pharmaceuticals both in tablets and in

other dosing methods. (41).

I have yet to find a good source of suitable grades

(cosmetic) for home use, but versions are now starting to become available as

toys as ’Yuck’ in the USA and ‘Slime Play’ in the UK (manufactured by Gelicity, sometimes carried in

Poundland). Both of these sources are relatively reasonably priced compared to

the available alternative methods of making slime.

Polyacrylamides were used in the Ghostbusters films to lend

stringiness to the methylcellulose based slimes.

Polyox

Slime

Polyox

Slime

(Coloured with cosmetic pigment)

Polyethylene

Oxide

Polyethelyne

Oxide (PEO) (or Polyoxyethelyne (POE)) is another high molecular weight

polymer, the common trade name being Polyox (16). Typically it will

have a molecular weight above about 100,000. Below this it will tend to

be known as Polyethelyne Glycol (PEG), the common trade name here being Carbowax

(17). Both PEG and PEO are widely used in cosmetics as well as such

items as vetinary lubricants (18).

Polyox

is pretty difficult to mix as a raw material (3). Commercial products

therefore mix other materials such as sugar to make dispersion easier

(18).

Psyllium/

Ispaghula Husk

Another

naturally occurring thickener- this is made from the ground up husk of

the Plantago Ovata seed. When mixed up it tends to form a stringy slime.

It

is sold in health food stores as a milled form as a form of dietary

fibre supplement, but in this form is not particularly soluble as it

clumps on mixing with water. For this reason there are a wide range of

purified and prepared formulations on the market, sold as bulk forming

laxatives. The formulations vary, but all have the common form of

coating the powdered husk with another substance to avoid the clumping

(19). The two most well known brands are Fybogel in the UK and

Metamucil in the US. Best results seem to be obtained by either boiling

a mixture of the husk powder and water or heating in the microwave for

a few minutes. Typically the concentration needs to be approx 2% by

weight, but as this is a natural product, there is significant

variation between supplier and batch (3).

Wallpaper

Paste

In

the UK it is difficult to obtain wallpaper paste that hasn't had a

fungicidal additive mixed in with it. For this reason I wouldn't

consider using it as a gunge. Chemically it is often a methylcellulose

grade or a Dextrin- a modified starch (4,7).

Theatrical

Slosh

A

perennial favourite in pantomimes in the UK is the slapstick scene-

epitomised by the laundry scene in Aladdin. The particular mess in

this and in clowning shows is generally known as slosh.

There

are many variations on the recipes for slosh, but the key features

are that it is soap based, and usually a foam (26).

The

common base recipe is to grate a shaving stick into a bucket,

sometimes quoted to be one manufactured by Erasmic (35,26,36), followed

by whipping up with hot/ boiling water. If manufacturing a bucket or

more, a paint stirrer attachment for a drill works well (3). One

stick with 1/2l of water and makes approx 1 Bucket of slosh.

Other

ingredients can be added including food colouring or poster paint to

colour the slosh (best added to the water first). I have also seen

cornflour, glycerine and gelatine quoted as other useful additives,

but haven't yet investigated these thoroughly.

A

further variation I have rarely seen is to dissolve soap flakes into

boiling water with a small quantity of glycerine and food colour

(3,37).

See seperate page for further details Slosh

Jelly/

Jello/ Gelatine

In

small quantities this is easily available and easy to make, however I

avoid using it for a number of reasons- Primarily it is difficult to

make in volume as it requires boiling water and refrigeration. Couple

this with the fact it's viscosity is temperature dependent and doesn't

store well when mixed makes it difficult to use. SAPs are commonly used

to give a jelly effect for example for wrestling in.

Denture Fixative

Denture

fixative has been sugeested as suitable to make a slime by those making

home movies (34). Wernets/ poligrip is available and contains a

cellulose thickener. It works but is an expensive way of getting the

thickener (3).

Cornflour

used for "walking on custard"

Cornflour

used for "walking on custard"

Cornflour

The

basis of custard, can form a highly thixotropic liquid when mixed with

water- This is the basis of the walking on custard demonstrations.

(e.g. the well known Brainiac episode). The proportion of Cornflour to

water need to be very high so this is not a cheap activity in large

volumes (3).

Guar

Gum Slime

Guar

Gum Slime

(cross-linked with borax and coloured with poster paint)

Sodium Alginate (E401)

Sodium

Alginate has been used for simulating thick fluids such as mud and tar

in TV use (38), but seems to have fallen out of favour in recent times.

It should not be confused with dental alginate used for lifecasting

which has additional chemicals to cause it to gel, rather than thicken.

Cross-linking

Some

of the thickeners have the ability to have their chains cross-linked to

make the viscosity much higher, by the action other chemicals. Both PVA (poly

vinyl alcohol) and Guar Gum are particularly good at cross linking with

a common chemical, sodium tetraborate- more normally known as borax

(4). The cross-linked guar gum is the material sold in toy

stores

as slime- but can be fairly easily made at home. There are good recipes

for this at 'Chemistry in the Toy Store' (20), along with a good

explanation of the chemistry and for a full recipe see the slime page.

Grades of thickener

Whilst I have treated the various thickeners as single

types, there is in reality a significant number of variations of each type, from

different manufacturers, and grades within their ranges. Typically the factors

that influence these grades include molecular weight and molecular weight

distribution, branching of polymer chain, powder sizes and ‘substitution’- the

addition of other chemical compounds onto the thickener chain. As there is such

a variety of possibilities it is always worth experimenting with the exact grade

you intend to use.

Brand Names And Trade Marks

Many

thickeners are sold under brand names or trade names, but in at least

some cases, a range of different types of thickener are sold under the

same brand name, with the discernable difference being the code for the

grade of the material. Particularly notable examples are Tylose and

Dow's Methocel- Whilst commonly Methyl Cellulose, a number of

other materials are sold under the same brand,.

Colouring

and colourants

There

are a number of options open for colouring the gunge, each with their

own benefits. I would recommend using products known to be safe for skin contact.

It is worth bearing in mind that to produce an intensely coloured

gunge, quite a lot of the dye will be needed- It is therefore inherent

risk that it will stain. To reduce the risk of damage to clothes, avoid

white or light colours and wash them as soon as possible after the

event, preferably before it dries on (3).

Whilst

most users will tend to colour their gunge with powder paints, liquid

tempera (poster paints) or food colourings there are a wide range of

other options available. Commercially, colourants are split in to two

main classes; dyes and pigments, defined as follows;

Pigment:

A pigment is a finely divided solid colouring material, which is

essentially insoluble in it's application medium” (21)

Dye:

Soluble colourant- may be soluble in water or other liquids

The

ideal colourant for our uses would be readily available in a wide range

of colours, non-staining, non toxic, vivid and available as both opaque

and clear versions, as well as being low cost. Unfortunately the

perfect solution does not seem to exist, so we are forced to compromise

on some factors, in particular with the commonly used colourants the

inherent risk is that it will stain. To reduce the risk of damage to

clothes, avoid white or light colours and wash them as soon as possible

after the event, preferably before it dries on.

A Wide Range of Possible Colourants & Professional Food Colours

A Wide Range of Possible Colourants & Professional Food Colours Colourants mixed at usable concentrations

Colourants mixed at usable concentrations

Food

colouring

Widely

available, safe and cheap. In my experience can stain quite badly as it

is a dye, and therefore designed to be absorbed onto food. It is clear

so means that mixed gunge will not be very visible when not in bulk (3).

Food colour for domestic uses is not normally sold as opaque

(certainly in common UK brands such as Dr Oetker), this may not be an issue if

you wish to create a clear, coloured goo, but if you want an opaque effect, you

will need to consider opacifiers. You may be lucky in some areas and find a gel

or paste available that has opacity, and whilst I have yet to find a UK source,

I understand that there are white food colours in existence in these

ranges.

Industrial food colours can however be bought as opaque

liquids, these are typically very viscous or paste (3) so that

the opacifier does not settle out in storage or transit. Opaque food colours type were

certainly used in Get Your Own Back.

Get Your Own Back Colouring

Possible options for more commonly available opacifiers

include milk (if you are using the goo immediately) and cornflour (cornstarch).

I have used flour, but it results in clumping and mixing difficulties as well as

difficulty in cleaning up the slime and fairly poor opacity as well.

Powder

Paints

This

is the colourant used in some of the commercial suppliers pre-mixed

powders (22). It is a pigment, so is generally less staining than food

colouring and is opaque (at least if mixed in sufficient

concentrations). It seems to be getting superseded for home kids

painting (in the UK at least) by the premixed paints, and is so

becoming slightly more difficult to obtain on the high street than it

once was.

The

composition is based on a pigment, an opacifier (usually titanium

dioxide), some binders (can be dextrose based) and an ‘extender’,

usually calcium-carbonate (chalk) (21). In my opinion the presence of

the extenders reduce the vividness of the colour, and for gunge, the

binders aren’t necessary. If someone could formulate a powder with

these changes, we’d have the perfect colourant!

However,tfor larger quantities of gunge, a suitable

chalk powder could be used as an opacifier and to reduce the cost of colouring

the slime, particularly as the cost of colouring to an intense, opaque shade can

be as much as the thickener in some cases.

I

believe it is the type of colouring used in at least some of the

commercially available suppliers products (22).

Liquid

Tempera (Poster Paint)

Widely

available, safe and opaque. These are a good all round choice,

particularly as the range of colours is wide and includes fluorescent

‘neon’. The colours do seem to be more vivid than the powder paints.

The main disadvantage is that some colours will stain, and a reasonable

quantity is needed to get a suitably opaque mix. I have also been

unable to find much useful information on the formulation, particularly

on binders or other chemicals used.

Helizarin

Helizarin

is a trade name of BASF, but is of note as it is the range of dyes

quoted as being used by the BBC for their gunge (6). It is not easily

available, although there is one trade source of small quantities in

the UK. It produces a very vivid colour, and is in my opinion the best

looking colour available, but it is not sold as safe for skin contact

(23), as well as being staining. I would not therefore recommend it for

home use.

Bath

Tints

These

are available as tablets for colouring bath water, and are sold under a

number of names, typically 'Fizzy bath tints'. They provide a way of

colouring that is not likely to stain, but only have a minimum of

colouring power (3).

Cosmetic

Dyes & Pigments

There

are a wide range of dyes and pigments available that are used in

cosmetics, and hence are safe to use. After spending some time

investigating and experimenting with these I have come to the

conclusion that for normal use they do not offer any great advantage

over the other options, and are not as easy to obtain. They main

benefit I can envisage with these are the availability of specialist

additives like pearlising agents and fine glitters that could add

‘sparkle’ to a gunge.

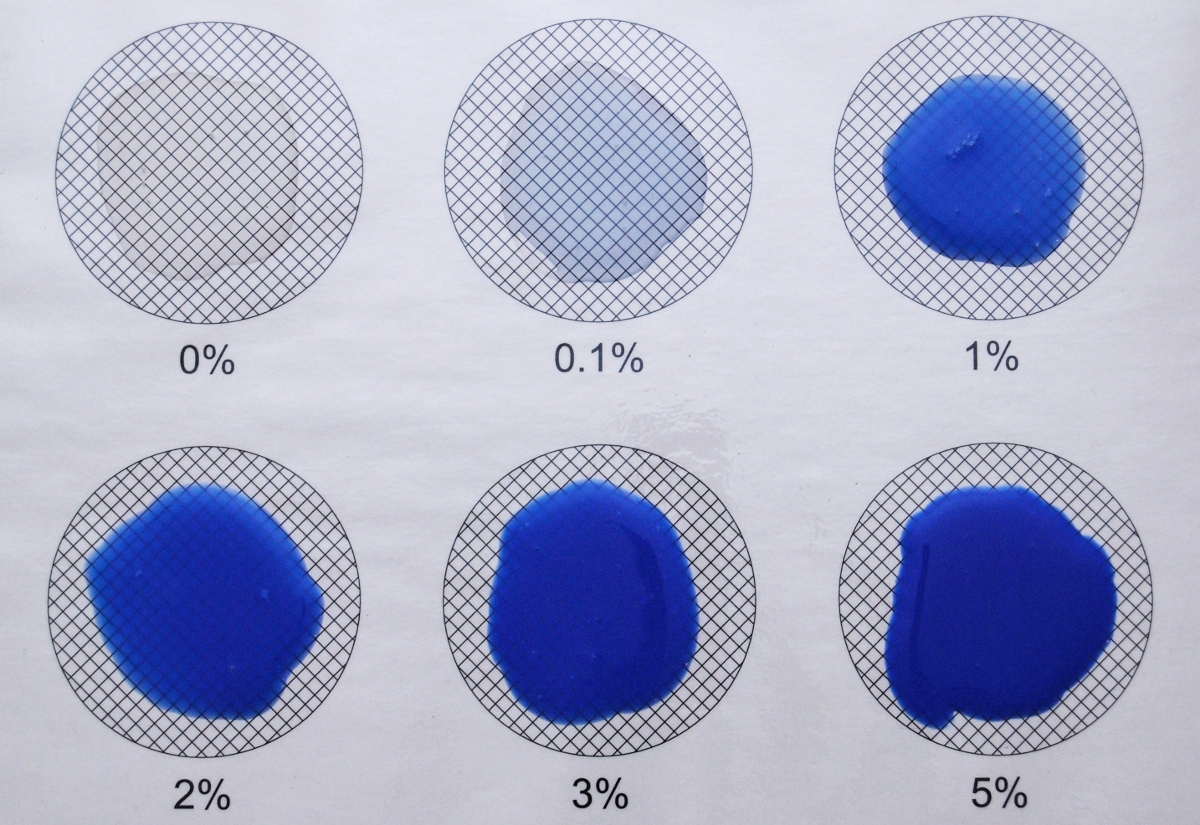

Colouring Intensity

Even a small amount of colourant will give an intense and

opaque effect when the gunge is in bulk, however when the gunge is in a thin

film, as will occur when it is being used, significantly more colourant will be

needed if you want the object/ person underneath to be obscured. Dependent on

the application, I will typically use between 1 and 2% by weight of powder

paint to produce a suitably opaque and intense colour. I have gone as far as 5%

when I have had a need to get a particularly strong effect in photographs. If

you need opacity, but not a vibrant colour then a mix of white powder paint to

provide the opacity and another colourant can give a desirable, but more pastel

effect.

These figures should be taken as a guide only as there will

be variation between different manufacturer’s paints and between colours in

their range. If a particular effect is needed then I’d recommend experimenting

first. It is also worth noting that at the higher concentrations, some of the

filler in the paint will slowly drop out of suspension. It is therefore a good

idea to give the gunge a good stir before use.

The following image gives some comparison of the opacity and

covering power of different concentrations, using Natrosol and NES Arnold blue

powder paint.

Paint ConcentrationsBlue powder paint mixed with water and Natrosol at 1%

Paint ConcentrationsBlue powder paint mixed with water and Natrosol at 1%

Further

Information

There

are a number of things picked up whilst researching this page that

don’t neatly fall under any other category, so I’ll include them here.

Rheology

There

is a branch of science devoted to researching and defining how

materials flow, known as Rheology. It is an area of research that has

wide ranging effects that might not be immediately obvious. Some

example areas are; flow of plastics in moulding & resins in

manufacturing composites, manufacture of paints, drilling mud for oil

well sinking, food processing and manufacture of the next ‘extreme

hold’ hair gel.

The

rheology of the materials is of interest to us- probably most

importantly, the viscosity of the material. This is described at the

start of this article. The other key properties that a fluid may have

that are interest are defined as;

Newtonian

Viscosity; Newton's law of viscosity states that the shear stress is

directly proportional to the shear rate (7). i.e. viscosity is

independent of the forces applied to the fluid, although temperature

may have an effect.

This

area will be expanded soon- please check back!

Cost

It

is difficult to determine categorically which gunge or slime will be

the most cost effective for your needs, but it is possible to compare

relative costs based on a finished volume. The following table aims to

do this, and is primarily based on UK pricing - Please bear in mind

there are many factors that have a bearing on the cost including

concentration, quantity bought, colouring, postage, material grade etc.

Although there are multiple factors to be considered, they are unlikely

to significantly alter the relative position in the list.

| Material | Concentration | Price Per Litre

Finished Gunge | Relative cost |

| Xanthan Gum | 1% | £0.07 | 1 |

Super Absorbant Polymer

'Gellibaff' | 0.25% | £0.08 | 1 |

| Guar Gum | 1% | £0.18 | 2 |

Hydoxyethylcellulose

'Natrosol' | 1% | £0.20 | 3 |

| Supermarket Xanthan | 1% | £0.24 | 3 |

Methylcellulose

'Methocel' | 1% | £0.29 | 4 |

| Gunge Powder | 1% | £0.94 | 13 |

Flourescent Gunge Powder

'Paint Party Powder' | 8% | £1.60 | 22 |

| Pre-mixed Gunge | N/A | £2.00 | 27 |

Compiled Feb 2014

Prices for uncoloured powder, nominal 1kg pack size

The

obvious conclusion is that unless you really need the convienence of

the smaller packaging (ie for one bucket), You are likely to be much

better off buying the raw powders.

Mixing

Mixing small quantaties of gunge is relatively easy, and shouldn't cause much

issue in producing a homogenous mix (ie not lumpy), however mixing large

quantities brings it's own issues.

I have recently mixed a large quantity

in one batch (500 litres) and have experienced some difficulties. On previous

occasions needing larger amounts (300-400l), I have always seperated the batch

into smaller quantities, typically of around 50 litres each, mixed seperately

and combined, typically using a paint mixer in an electric drill. Whilst some

care is needed to ensure the thickener is added at a suitable rate to avoid

clumping, the power of the mixer is sufficient in this size batch to keep it

well agitated, and hence get a good mix.

When the process is scaled up, a

drill mixer isn't adequate to mix the whole tank simeltanously, and hence any

thickener missing the mixing zone will sit on the surface for some time, and

tend to clump. The problem gets worse as time goes on as the viscosity of the

mix increases, and hence hinders mixing further. In the recent experience this

meant we ended up with the 'fish eyes' layer of not fully mixed material on the

surface. Once this has occured it is very difficult to recover from. For this

application it wasn't a major problem, but were viscosity be needed to be

closely controlled it may be an issue.

Should you therefore need to mix

large quantities I would recommend mixing in as small a batch as practical, and

using the most powerful stirrer available (may be a plaster mixer) as well as

being as careful as possible to pour the powder into the agitated are of the

mixing only (3).

For more details on mixing bulk quantities, please se the bulk page; Bulk Gunge

Movie

Slime/ Monster Slime

Apart

from the bulk quantities of slime that is used in movies usually being

manufactured from methyl cellulose (8,11) there are a number of other

substances used. The most obvious being the use of KY Jelly in the

alien films (11). The one however of most interest is Ultra Slime.

Ultra Slime is manufactured by a company called Ultra Materials. For a

few years it appeared they weren't r trading and so the mantle of

providing stringy slime fell to a couple of other

companies, however they seem to be back in business again in 2015 (44).

The companies that produce this type of slime understandably don’t

publish

the formulations, however from studying of a material safety data sheet

(29), and by experimentation (3), I would postulate that the key

ingredient is polyox or polyacrylamide which is blended with

methylcellulose.

Similarly

the other commercially available stringy slime powder, ‘Sticky Yuck’ I

would postulate is a blend of Polyox and sodium polyacrylamide

(3,14,15).

Nickleodeon Green Slime

One

of the most well known users of slime is the children's television

channel Nickeleodeon. The slime they use is manufactured by a company

called Blair Adhesives in the US (30,31,32,33).There is no indication

of what the slime is based on, although the colouring is known to be

food colouring (32)

Safety

Whilst

I have been careful to only list materials on this page that are not

known to have any significant health risks associated with them, they

cannot all be classed as completely hazard free.

The

largest single issue is the slipperiness of the mix- it can be very

easy to slip over on. It is therefore essential to consider this when

planning any activities involving gunge, including clean up and washing

off as the most significant effects will be found on a smooth surface

such as a bath!

Most

of the materials are supplied as relatively fine powders, and as such

create nuisance dust. It is therefore worth wearing a dust mask when

handling. Likewise if this dust gets into eyes it can cause irritation.

Most

of the materials are sold as safe for skin contact (e.g. cosmetics) and

to date I have not had any problems with this. I would however be

slightly wary of allowing prolonged skin contact with the colourants as

it may stain!

All

of these main materials (with one exception- see below) are not

hazardous when eaten, however many are used as laxative additives, so

it would probably be unwise to consume large quantities (4)!

Borax

(Sodium Tetraborate) is the main exception to the above- It is not safe

for consumption, and should therefore be handled and used carefully so

as to avoid ingestion, although in the quantities actually present in

slime it should not cause any concern. (27)

In

addition to the specific information above, general safe chemical

handling practice will further reduce the risk of any issues, in

particular;

Store

materials in sealed, well marked, containers in an area out of reach of

children and pets

Wash

hands before and after handling these materials

Dispose

of excess/ used materials/ empty packaging responsibly

Wear

dust mask when handling powders

Clean

up any spills quickly- Avoid using water to stop the area becoming

slippery

Do

not use utensils/ containers/ cleaning cloths that will be later used

for food

Unsafe Materials

There may a temptation to use other thick or gooey materials

for messy activities, and some may be tempting due to cost and availability. I

would strongly recommend not using products other than those known to be safe-

in particular I would suggest that you do NOT use any of the

following;

Plaster (building, casting or plaster of paris)

Risk of burns. Plasters give off heat as they cure, which can

be intense. There is at least one case of amputation needed after plaster burns

(42).

Cement

Risk of Alkali burns. Cement has caused many recorded issues

for workers in contact with cement during the course of their employment (43).

Paints

Unless sold as children’s paint, I would avoid any other

types of paint due to the presence of solvents, other toxic ingredients and in

some cases heavy metals in some types. Unless you are familiar with the

chemicals used it will be difficult to ascertain the risk of any particular

type.

Motor oil/ Grease (Especially used)

Risk of dermatitis or cuts. Used oils can contain complex and

unknown compounds that can be hazardous to health. Metal particles may also be

included.

References

(1)

English Dictionary, Home Edition, Collins, ISBN 978-0-00-784932-1

(2)

Materials Science and Technology Dictionary, Prof P.M.B. Walker,

Chambers,

ISBN 0-550-13249-x

(3)

Personal experimentation

(4)

Industrial Gums- Polysaccharides and Their Derivatives, Second Edition,

Roy

Whistle, Academic Press 1973, ISBN 012746252

(5)

http://www.thesoapkitchen.co.uk/

(6)

BBC red nose day website 1999

(7)

http://www.britannica.com/EBchecked/topic/160522/dextrin

(8)

Quest- Marshall Cavendish Partwork

(10)

Rosie O'donnell show interview with Sigourney Weaver, Nov 26th, 1997

(11)

Alien The Special Effects, Don Shay & Bill Norton, Cinefex ISBN

1-85286-695-0

(12)

http://www.m2polymer.com/html/chemistry_sap.html

(13)

Gellibaff MSDS- http://www.gellibaff.com/uploads/1/3/6/3/13638060/msdsheet-4.pdf

(14)

Superabsorbent Polymers Science and Technology, F.L.Buchholz &

N.A.Peppa, ACS Symposium Series 573, ISBN 0-8412-3039-0

(15)

Buckets of Yuck MSDS- http://www.buckets-o-fun.com/gamesheets/MSDS.pdf

(16)

Dow Polyox Water-Soluble Resins Datasheet- 326-00001-0302 AMS

(17)

Dow Carbowax and Carbowax Sentry Datasheet- 118-1260-0306 AMS

(18)

J-Lube MSDS- http://www.jorvet.com/msds/j_lube.pdf

(19)

Patents; US20050031714, US4321263, US5126150

(20)

http://www.chymist.com/toy_store.html

(21)

Colour Chemistry, R.M. Christie, RSC Paperbacks, 2001, ISBN

0-85404-573-2

(22) Youtube video for thegungeshop.com-

http://www.youtube.com/watch?v=9G0lPyRKLqM

(23) Concentrated Liquid Pigment MSDS- Flint Hire and Supply

(24)

http://www.britannica.com/EBchecked/topic/160522/dextrin

(25)

Dow Methocel Cellulose ethers technical handbook, 192-01062-697GW

(26)

http://amdram.co.uk/forums/index.php?showtopic=5342&hl=slosh

(27)

http://www.thesoapkitchen.co.uk/images/MSDS/powders%20&%20granules/MSDS%20Borax.pdf

(28)

http://www.cosmeticsbusiness.com/technical/article_page/Repeat_performance/47074

(29)

Super Goop MSDS, Roger George Rentals

(30)

http://www.nick.com/shows/kids-choice-awards/pictures/kca-2010-making-of-flipbook.html

(31) http://www.blairadhesives.com/Special_Effects.html

(32) http://blog.zap2it.com/tvfashion/2010/03/to-a-funeral-we-wear.html

(33) http://www.nytimes.com/2008/03/29/arts/television/29nick.html

(34) http://www.theeffectslab.com/forums/viewtopic.php?t=1786

(35)

http://www.erasmic.co.uk/shave-brush.html

(36)

Conversations with professional stage manager

(37) Blue

Peter episode late 1980s- from memory

(38) Special Effects in Television, Second Edition, Bernard Wilkie, Focal Press, ISBN 0-24051361-4

(39) Water Soluble Polymers: SNF Floerger product brochure. http://www.snf-group.com/

(40) Flocare: SNF Cosmetics product brochure. http://www.snf-group.com/

(41) Water Soluble Polymers for Pharmaceutical Applications.

Veeran Gowda Kadajji and Guru V. Betageri . Polymers 2011, 3,

1972-2009

(42) http://news.bbc.co.uk/1/hi/education/6485481.stm

(43) http://precast.org/2010/05/cement-burns/

(44) http://www.ultramaterials.com/

Supplier

Details

I understand the Basic Chemical Company are no longer providing Natrosol as of 2023

The

Basic Chemical Company (UK) Ltd

Hillbottom

Road

Sands

Industrial Estate

High

Wycombe

Buckinghamshire

HP12

4HJ

01494

450701

http://www.basicchemicals.co.uk/

The

Soap Kitchen (warehouse),

Units

2 D&E Hatchmoor Industrial Estate,

Hatchmoor

Road, Torrington,

Devon

EX38

7HP. UK.

01805

622944.

http://www.thesoapkitchen.co.uk/

A

significant amount of effort has gone into researching this page.

Please do not plagiarise this work without contacting me for permission

first- I will usually say yes! This page will be updated periodically

as and when new I find new, relevant information.

As with other projects on this

site, feel free to contact me if you have opportunities to use the

technology- I am always interested in collaborating on interesting projects, be that

photographic, TV, Film, Nightclub, Exhibitions or other uses. Contact details are

on the about me page.