Whilst most people using this site will probably be happy to

make a few litres or a bucketful of gunge or slime, there will always be those

that need to make more. This page is therefore aimed at providing information

that may be of use if you want to produce larger quantities (even as far as

filling a swimming pool). Please read the other general gunge pages first to

understand the basic properties & general choices.

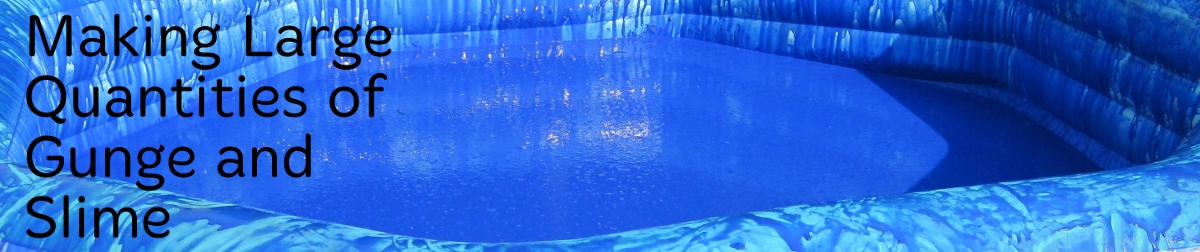

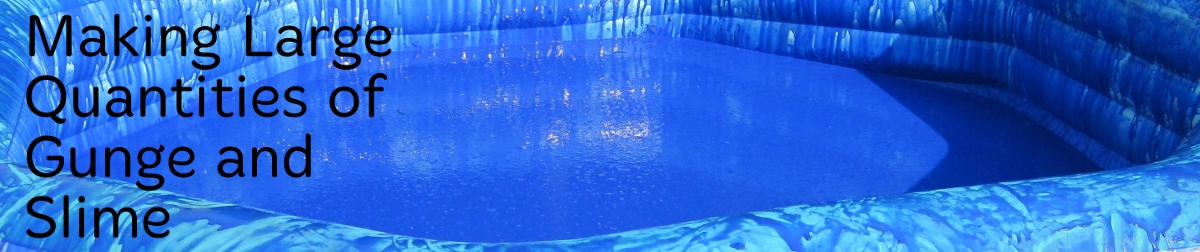

Quantities up to 1000-2000 Litres

The

main part of this page is valid up to quantities of around 1000-2000

litres, although this not a hard and fast limit. It will therefore suit

most intermediate users such as those wanting to fill paddling pools,

dunk tanks or ‘slime run’ obstacles. Quantities above this may

favour different techniques, but I have produced approximately

8000 litres successfully using these methods.

Thickener

The first consideration will be which substance to use.

There are two main issues here; Cost and ease of mixing.

Cost

Many

of the possibilities described in the other pages of this website will

not be cheap enough to make a large quantity practical. This leaves two

main possibilities; Guar Gum and Xanthan Gum. At the time of writing,

they are approximately equivalent in price, I would therefore use

whatever you can be obtain at a reasonable cost, but bear in mind

whilst comparing cost per kilo that the grade chosen can affect the

viscosity of the mix.

Many of the options of thickener work best when mixed in hot

water, and in some cases like Natrasol this is essential. Thankfully both Guar

Gum and Xanthan Gum both mix into cold water well.

Gunge proportions

I normally work with proportions of 1.5% thickener, but when

in bulk you may be able to reduce this somewhat. I would postulate that the

proportions used in the iconic game shows ‘Run the Risk’ and ‘Get Your Own Back”

are a lower proportion. The images on this page use 1.5%

thickener.

As for smaller quantities, I would recommend using powder

paints as the colourant. I will typically use 3% by weight where the colouring

needs to be strong and when the coverage on people needs to be opaque. The

images on this page use this proportion. If the colouring needs to just work in

bulk, then the quantity can be massively reduced. Bear in mind that at 3%, the

colouring may stain light fabrics, so the choice of concentration would need to

take account of this.

You will need a sufficient water supply directly available

where you are mixing, as well as a power supply. The flow through a domestic

hose can be quite low, so it is worth planning beforehand to make sure you get a

sufficient flow. The speed that the gunge can be made may be related to how fast

you can fill the containers you are using.

Equipment

There are a number of possible ways of mixing the gunge, but

my preferred option up to about 1000 litres is now to use a plaster mixer and a

couple of plastic drums of about 60 litre capacity.

It is possible to mix the gunge in bulk, putting the quantity

of water needed into the pool/ tank you are using and stirring the colourant and

thickener. In my experience, producing about 400 litres this way, it is very

difficult to get a thorough mix as you need a powerful mixer to get the full

volume of water circulating quickly enough to get good thorough mixing- indeed I

burnt out an electric drill doing this and ended up with somewhat lumpy gunge.

It is possible to obtain mixers to go into a standard drill, and for smaller

batches these can be effective. The plaster mixer is however more suited to the

larger batches as they are generally more powerful, operate at a suitable speed

and have a slow start- for a one off they can usually be hired.

Process

My preferred production method starts with pre-weighing

ingredients into plastic containers so that they are ready for use. Bear in mind

that these need to be kept dry up until they are used so you may need to cover

them or weigh indoors if there is any chance of rain or splashing. It is also

important to make sure all items coming in contact with the gunge are

clean.

In parallel I will fill the plastic drums using a hose until

they reach about 50 litres. It is useful to have some headspace when mixing, so

50 litres in a 60 litre drum works well. I tend not to use significantly bigger

drums as the 50 litres can be lifted and carried between two people easily.

The plaster mixer is then used to stir the water thoroughly whilst the colourant and thickener is added.

Disposal

Consideration needs to be given to the best method of

disposing of the gunge after use. I would avoid directly dumping the thick

material into a sewer to avoid any chance of blockage. The gunge will degrade

after a few days back to water, so if time is available it can then be run to

sewerage safely.

In some cases we have tipped out the material onto grass- the

water is absorbed quickly. The remainder is then primarily colourant of which

the bulk is chalk.

An alternative is to have the gunge collected by a liquid

waste company- this is likely to be the most environmentally sound method, but

also the most expensive.

The resultant goo

Very Large Quantities

Quantities exceeding 1000-2000 litres will almost certainly

need different techniques, although the majority of the factors discussed above

will still be valid. I am aware of very few instances where this sort of

quantity has been used so will discuss these as case histories;

The Mythbusters produced an episode where they tested the

myth of swimming in treacle vs. water. For this they used guar gum and used a

cement truck to mix. From the footage it is clear the mixing was ineffective as

the material ‘fisheyed’, partially gelled with solid lumps which tends to float

to the surface. I would postulate that mixing in this way is not sufficiently

high shear to be effective.

Nickelodeon have produced a number of stunts over the past

few years, some of which have used significant quantities of slime- this has

been commercially supplied by Blair Adhesives, in one case at least shipped in

by tanker. Notable here is that Blair Adhesives will have commercial equipment

designed to mix large quantities in significant batch sizes away from site. This

would seem to be the most effective method to me- elsewhere I am sure contract

manufacturing could be used.

In 2005 a team from the University of Minnesota one the

IgNobel prize for their research as to whether it is quicker to swim in syrup or

water. To achieve this they thickened up the water in their university pool with

guar gum, but in very low concentrations, hence the mixing wouldn’t have been as

difficult as would be envisaged.

If

you are looking at an event where very large quantities of gunge are

needed (above about 2000 litres), then I would suggest it warrants

investigating a contract manufacturer to pre-mix it away from site. If

sufficient water supplies are available, a tolerance for a small

quantity of lumps is possible and mechanical handling is available, the

use of tipping skips of 500-100 litre capacity would provide a route to

production on site. Other industrial mixing equipment may prove

possible to use too.

If making the goop in advance, or needing to keep it in use

for some time, then it may be necessary to use preservatives as degradation can

occur in a few days (especially in hot conditions).

It should be noted that any structure needed to contain large quantities will also need careful consideration and design to withstand all the forces on it.

Further information

For further sources of information, and on services

superpants.net can offer your event, please see the further info

page.

Photo Credits

Many thanks to those that provided photos for this web page,

copyright of these remains with the photographer (c) 2013;

http://www.flickr.com/photos/ice_badger/

http://www.escapedcreativity.co.uk/