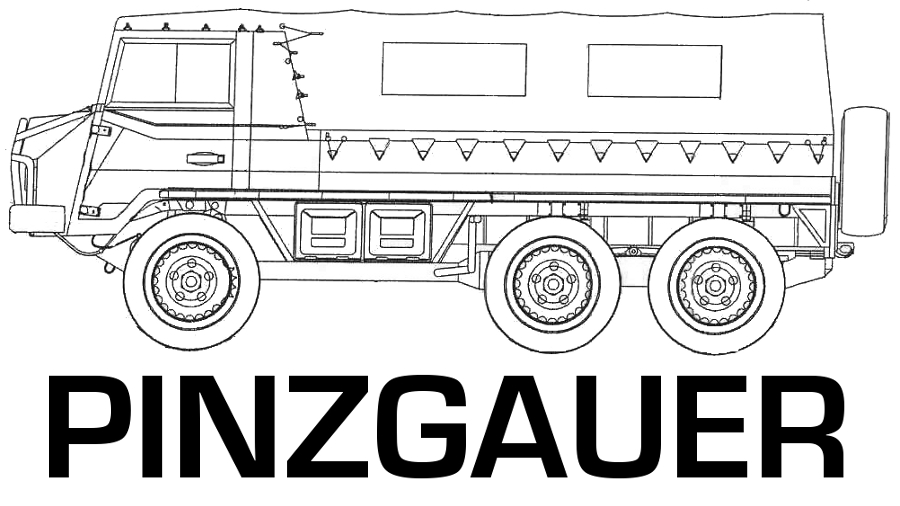

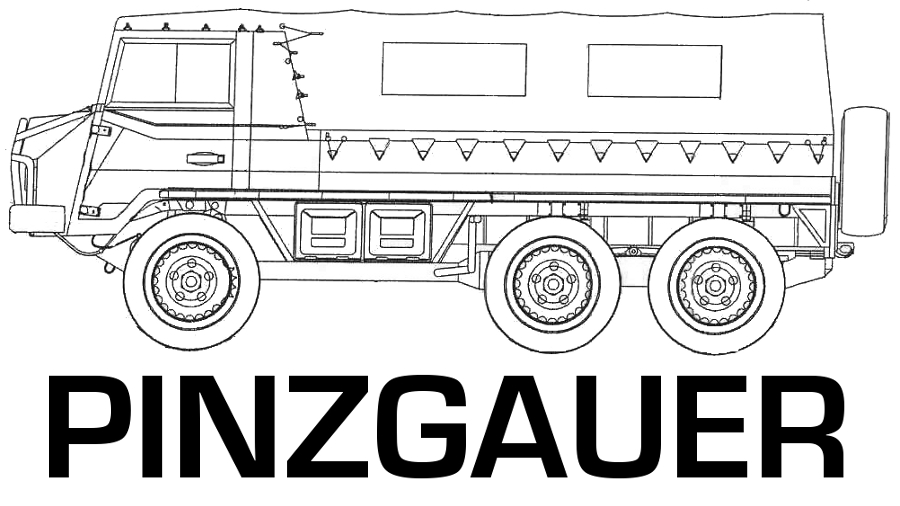

History

From 2003 to 2008 I worked at Pinzgauer at its Guildford

site. During the time I was there the company went through a number of changes

of ownership, with varying degrees of success. The following is a brief history

from my own point of view- whilst I have tried to be as accurate and honest as

possible, some points remain speculation.

At the point I started, the business was called Automotive

Technik Limited, an independent company owned by Alan Mawer and David Findlay

with investment from Close Brothers. The team had started out in a portacabin in

Aldershot as UK agents selling the Pinzgauer being built at that time in Austria

by Magna-Steyr.

By the time I joined, the company had taken on the sole

rights to the vehicle and had relocated the production line from Austria to the

UK, with the body in white (BIW) plant in Fareham and final assembly in

Guildford. Paint was carried out as in interim step at LDV before delivery of

the body to Guildford.

Initially the vehicle was made in small volumes of a few a

week, largely from kits of parts supplied from Magna Steyr, with required parts

selected from the parts books, but as time went on many of the parts were

re-sourced to the UK. Up to the end Magna Steyr remained the biggest single

supplier, but primarily due to the volumes of pressed panels and cast parts they

supplied.

At the point I started the first build of a new Euro III

compliant vehicle was happening, with the build of an Engineering truck, J108.

Roush had been engaged to do the engine integration, and supplied kits of

components to fit the engine into the existing truck. This engine was the

Volkswagen 2.4TD, 5 cylinder variant, used in some of the VW van range, and very

similar to the smaller version used in vehicles such as the Passat at the time.

Whilst the installation worked, it was a long way from being a robust, easily

manufacturable solution. Myself and a couple of other new Engineers who all

joined within a couple of months, led by a new Engineering Manager, Jonathan

Etherington, were given the task of productionising the product. This took the

form of simplifying many of the brackets and other parts, liaising with

suppliers for production ready parts such as the engine cover, and rationalising

the electrical harness design.

As time went on my role transformed into looking after all electrical systems on the vehicle, and so I got involved with both electrical matters on the base vehicle as well as installation of customer equipment such as the BOWMAN radio system and the idiosyncrasies of ambulances and fire engines.

Working

under the original owners was highly enjoyable- there was a great team

spirit, and as engineers we had interesting projects to work on. The

owners were also keen for us to get experience with the vehicles, so we

were encouraged to borrow trucks over the weekend, especially when new

parts needed trialing.

ATL was successful in winning a large contract for radio

vehicles for the UK army, a total of 400 off, codenamed TUM FFR which was a

great boost to the company, but came the with the pains of growing production to

around 10 vehicles a week, and as well as the attendant logistical challenges

that brought on the cramped site at Guildford, it of course also made cash-flow

difficult. It was only natural then that the business owners looked for

investment and finally chose to sell to Stewart and Stevenson, who at that time

were a large US manufacturer of military trucks, with the contract to

manufacture the FMTV (Family of Medium Tactical Vehicles). The fit was natural

between the two companies; S&S got to diversify into smaller vehicles and

gained a presence in Europe and ATL conversely got support for US markets as

well as the necessary funding to make it secure.

After about a year under S&S ownership, Armor Holdings

purchased S&S as a way of expanding their general business of armour into

the vehicle field, again this was a fairly obvious acquisition, and it made only

small changes to the day to day running of the business, beyond the usual

changes of brand.

In 2006 BAE sold it’s 20% stake in Airbus for 2.75 Billion

Euros (£1.9 Billion)(1). BAE therefore had cash in the bank and in July 2007

bought out Armor Holdings (2), to significantly widen its market

share in the US.

Pinzgauer was a very small part of the BAE empire, and

consequently didn’t seem to be taken seriously, as can be seen by the cessation

of production and redundancies in mid 2008 and subsequent complete closure of

the two sites (3). BAE no longer actively offer the product range. My suspicion

is that as the vehicle already had a known cost in the marketplace, BAE couldn’t

change this to meet its corporate profit expectations. If the vehicle is no

longer manufactured, when the time comes for the MOD to replace the Pinzgauer

fleet, BAE or another company will be able to charge the MOD to design a new

product, and with the pricing history of the Pinzgauer no longer relevant, will

be able to charge significantly more for the vehicle as well as profit from the

engineering.

I find it now highly ironic that BAE sold its share in

airbus, likely because it couldn’t see enough profit, to buy US military market

share that failed to materialise, and has recently been trying to buy back into

Airbus. When the contract for supply of the FMTV was up for renewal BAE lost it

to Oshkosh Defense, a US headquartered company (4). I’m glad I don’t have BAE shares

with that level of frittering of money, although it’s

rather galling as a taxpayer- the largest customer!

Vector

There has been quite a lot written suggesting that the Vector

vehicle was not fit for purpose, which is difficult as one of the Engineering

team involved in developing the product. A lot of the criticism levelled at the

vehicle should really have been aimed at the requirements we were asked to meet,

and to the uses the vehicle was put to.

The vehicle project was an Urgent Operational Requirement

(UOR) that took less than a year from initial concept to delivery to

Afghanistan. The level of armouring was dictated to us, but with some very tight

requirements on manoeuvrability- our usual being ‘Improved Medium Mobility’. To

the best of my knowledge there wasn’t a product that could meet all these

requirements, and even now after years of development, there is little on the

market.

The original Pinzgauer had a good level of reliability,

partially due to the good margins in the strengths of components. Increasing the

weight of the vehicle, whilst still maintaining the manoeuvrability naturally

meant that these margins were eaten into, and so failures started to be seen-

particularly where the vehicle met very harsh ground conditions or was overladen

and hence updates were introduced during the vehicle life to address these

problems.

Pinz II

Considerable effort and resource went into developing the

replacement of the original Pinzgauer, a programme that lasted in total around 3

years and resulted in demonstration of a development mule and several prototypes

and was launched at the DSEI show in 2007. Several fundamental issues with the

vehicle drove the programme and included:

Lack of available power for more heavily laden vehicles,

hence a requirement to use a larger engine

Changes to emissions requirements requiring a new engine, and

more complicated exhaust treatment

Higher cooling capability of larger engine driving changes to

the bodywork around the cooling duct

Improved ergonomics of the cab to enable large soldiers

wearing body armour and helmet to easily operate the vehicle

Roll over protection of the Cab

Obsolescence management- many components used dated back to

the 1970s and so sourcing was difficult

There were a wide range of other improvements made and as a near ground up approach was taken, the only major carry over parts were the axle assemblies.

Mantis

The Pinzgauer was represented in the USA by Advanced Vehicle Systems Inc, and

whilst the sales of new vehicles were small, they were well received by the

military customers that were being courted. The US market tended to favour a

bonnet forward rather than a forward control design and so AVS developed the

‘Mantis’ concept of the Pinzgauer II design, taking much of the powertrain work,

and producing an alternative body. To the best of my knowledge none were

sold.

Spare Parts

Users of the Pinzgauer generally only now have one official source of spare parts- BAE systems, however If you are struggling to source components I recommend contacting Haflinger Technik. They have extensive stocks of genuine spares and have been able to re-source or re-manufacture many others. Haflinger Technik

Gallery of Images

Haflinger- the Forerunner of the Pinzgauer and an Earlier Air-Cooled Pinzgauer

Three P93 Pinzgauers at All Wheel Drive Club Forward Control Day

The Manual P93- owned by ATL, known as NATS

J108 the Euro III Development Vehicle

'The White Truck' was used for other development work. the LH image shows a new cab design, on the right we

were testing the power and aircon system for the Vector vehicles

Out with the Trucks at Walters Arena South Wales

WMIK Variant Produced by Ricardo

(3) http://news.bbc.co.uk/1/hi/england/7376589.stm

(4) https://en.wikipedia.org/wiki/Oshkosh_Corporation