How to Make a Quality Crimped Joint

A Range of Finished Crimps With Tools

A Range of Finished Crimps With Tools

Whilst

understood well within professional harness makers, the correct

application of crimps is something that doesn’t seem to be as widely

understood in DIY circles with much information available ranging from

not very thorough to out-rightly wrong; One of my friends was once

given the advice by an employee in a car hi-fi shop to hold the crimp

onto the cable with insulating tape and nothing else....... Crimping is

a technique that can produce reliable, long lasting joint, efficiently

and easily with very little training.There

are a vast range of crimps out there in the market- industrial users of

crimps have good access to information from the crimp and tooling

manufacturers so I won’t go into depth on these applications. Instead,

in this Instructable I hope to give some advice on using crimps that

you are likely to encounter in installing accessories or making repairs

to your car, boat or caravan or in projects at home.Much

of this page will focus on materials and tools, so I will split this

down into detail in three main areas and will keep the introduction

materials simple:MaterialsGood quality crimp terminals to suit the applicationStranded wire of a known specification (not solid core)Heatshrink ToolsGood quality wire cuttersCrimp tool to suit the terminals Step 1 Choosing the wireDepending

on your application, you may or may not have a choice on the wire to

use. Firstly do not use solid cored wire, and if you want a reliable

job heavily avoid ‘conduit wire’ (a few largish strands intended for

mains buried in conduit). Specific types of crimps are required to use

this type of wire reliably. The best wire for general use will be one

with many strands. Wire Types

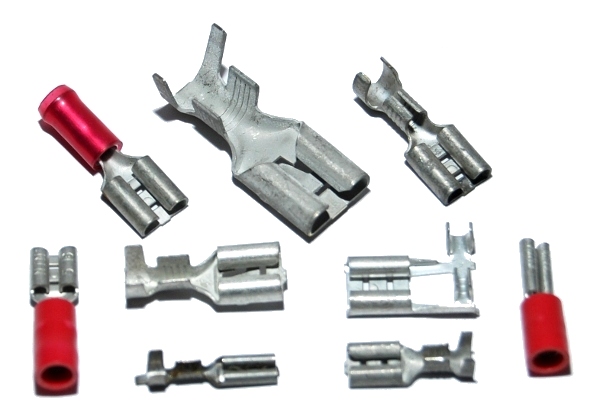

Wire Types A Range of Possible Crimps

A Range of Possible Crimps Preinsulated Crimps- (better quality terminal on the left

Preinsulated Crimps- (better quality terminal on the left)

Common Three Sizes of Insulated Crimps

Common Three Sizes of Insulated Crimps Sheet and Tube Formed Crimps

Sheet and Tube Formed Crimps Blade Type Crimps

Blade Type Crimps Junior Power Timer Crimp Kit

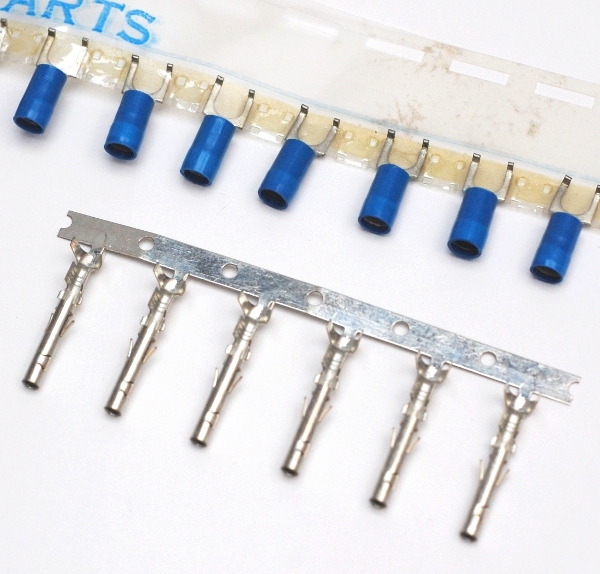

Junior Power Timer Crimp Kit Crimps as Packaged For Volume Production

Crimps as Packaged For Volume Production A Wide Range of Crimp Tools

A Wide Range of Crimp Tools

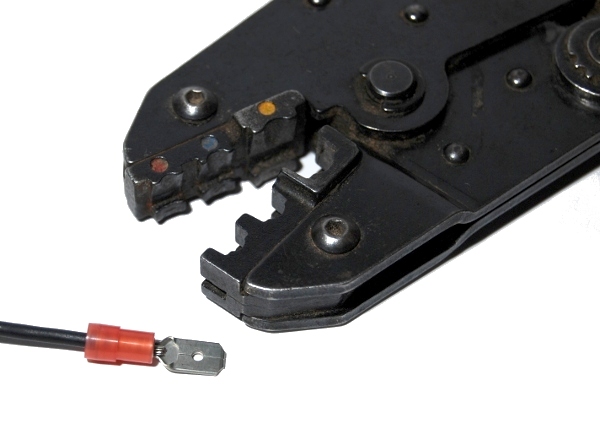

Wire in Crimp With Tool, and Finished Termination

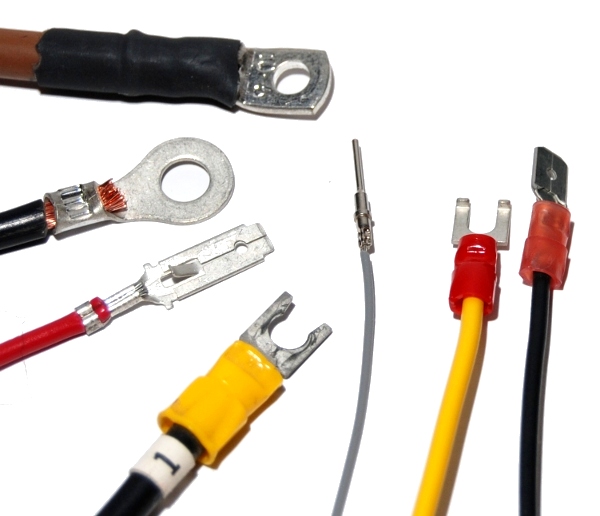

Wire in Crimp With Tool, and Finished Termination Finished Crimp Terminations

Finished Crimp Terminations Heatshrink Insulated Terminal

Heatshrink Insulated Terminal

(c) M.Pantrey 2012